about us

We are FB Group

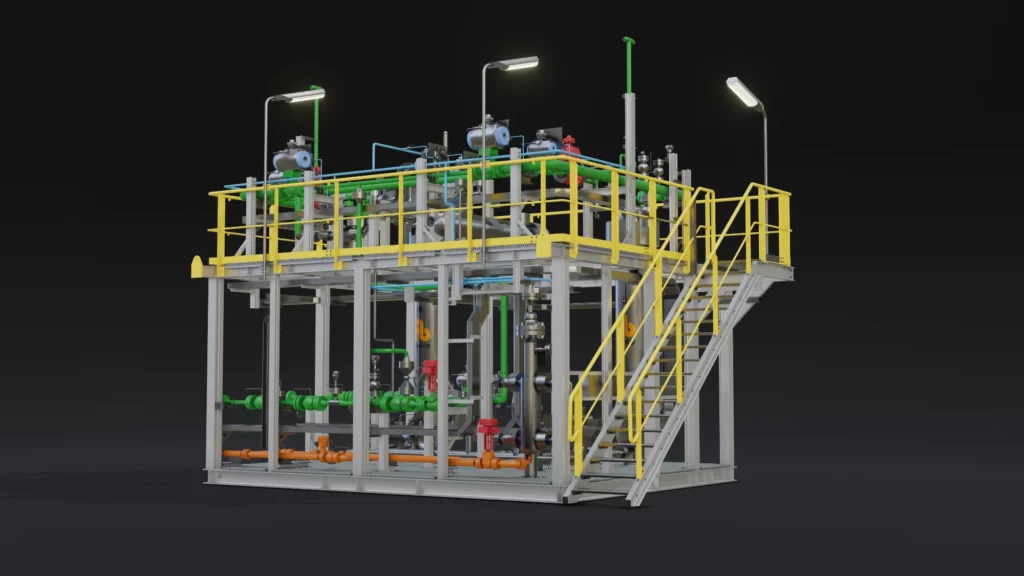

At FB Group, we specialize in delivering skid-mounted process units to support the Global Energy Transition. We are a dynamic organization driven by enthusiasm, resilience, and a commitment to excellence, guided by a straightforward, ‘no-nonsense’ approach. Our highly skilled and experienced team ensures we deliver innovative, high-quality solutions tailored to your needs.

Our packaged unit design philosophy enables us to turn complex challenges into customized, high-performing products. From design and engineering to fabrication, we transform your requirements into fully integrated skid-mounted process units.

At FB Group, shared responsibility drives ownership of your project. By proactively understanding your needs, we become an extension of your vision to help you succeed.

what we do

Building the Energy Transition

The energy transition is the shift from non-renewable to renewable energy sources, reducing greenhouse gas emissions, enhancing energy security, and fostering sustainable economic growth.

This transformation progresses gradually, balancing technical and economic possibilities. Temporary measures like Carbon Capture Storage (CCS) or transitioning to natural gas help reduce emissions while technologies like hydrogen are scaled for industrial use.

FB Group plays a key role in this shift by delivering process packages that enable practical solutions for a sustainable energy future.

Building on our past

At FB Group, we take pride in leveraging decades of expertise in natural gas processing, offshore solutions, and chemical plants to propel the energy transition forward. Our extensive experience and proven results empower us to make a tangible impact on creating a cleaner, more sustainable future.

Decades of Expertise

With a long-standing presence in the industry, we bring unparalleled reliability and knowledge to every project.

Innovative Technology

We leverage cutting-edge technology to deliver sustainable and cost-effective energy solutions.

Commitment to Sustainability

Our mission is to reduce greenhouse gas emissions and promote renewable energy for a better future.

Proven Track Record

With numerous successful projects, we have consistently delivered measurable reductions in energy consumption and carbon emissions.

Our process

Together we create unparalleled systems.

Sales & Concept

We make use of advanced manufacturing techniques to provide with the highest quality of products.We make use of advanced manufacturing techniques to provide with the highest quality of products.

Design & Engineering

We make use of advanced manufacturing techniques to provide with the highest quality of products.We make use of advanced manufacturing techniques to provide with the highest quality of products.

Sourcing

Establishing production facilities reduces shipping distances, allowing for faster fulfillment of orders.Establishing production facilities reduces shipping distances, allowing for faster fulfillment of orders.

Fabrication

We meticulously work with the client to provide the most pleasant work relationship while working. We meticulously work with the client to provide the most pleasant work relationship while working.

Assembly

We meticulously work with the client to provide the most pleasant work relationship while working. We meticulously work with the client to provide the most pleasant work relationship while working.

Testing

We meticulously work with the client to provide the most pleasant work relationship while working. We meticulously work with the client to provide the most pleasant work relationship while working.

Sales & Concept

The sales process begins with identifying potential clients, understanding their needs, and presenting tailored solutions. This process includes drafting proposals, addressing technical and commercial details, and finalizing an order agreement.

Design & Engineering

Once the order is secured, the first step is to develop the Basic Design of the unit. This involves Process Engineering, performing equipment sizing calculations, and creating Process Flow Diagrams (PFDs) and Piping & Instrumentation Diagrams (P&IDs).

Sourcing

This phase focuses on procuring all necessary materials, components, and services for the project. It includes identifying suitable suppliers, negotiating contracts, and ensuring the timely delivery of high-quality materials.

Fabrication

During the fabrication phase, components such as pressure vessels, steel structures, and piping systems are manufactured and assembled. This work is performed in FB Group's workshops by skilled professionals.

Assembly

In the assembly phase, the fabricated components are brought together to create the final product. This includes mechanical, structural, and instrumentation assembly in accordance with the design specifications.

Testing

The final phase involves testing the assembled product to verify its functionality and compliance with performance and safety standards. This includes functional tests, quality assurance checks, and, if required, full Factory Acceptance Tests (FAT).

latest

News updates & recent projects.

Stay informed about recent developments.